OEM

Production

- HOME

- Outline of Business

- OEM(English)

Our skilled artisans create figures that are recognized as

the best works of artistic craftsmanship of their type in the world.

We utilize a proprietary leading production management system to achieve this result

Since our establishment over twenty years ago, we have planned and produced works of arts and crafts as well as figures. This has permitted us to constantly pursue the highest level of custom-made quality in the manufacturing of our figures.

At the time of our company’s inception, we started out as the world’s largest maker of made-to-order garage kit figures. This experience enabled us to build the production expertise to handle stringent requirements, and meet the detailed and complex needs of our customers.

Our production methods for figures are fundamentally different from other companies.We take an original approach with production methods, the cultivation of human resources and all other matters from the standpoint of creating one-of-a-kind products.

This has let us perfect our system processes – from high quality production to packaging methods incorporating countermeasures against damage for international shipping.

No other company cannot imitate us. The consistency of our personnel – from recruitment to training – is also key to the smooth execution of our business.

OEM Product

• High quality OEM production

• We accept orders for figures and custom-made products

• Minimum production: 50 units

We can produce complex and intricate shapes in their original three-dimensional form and can create advanced modeling that is not limited by molds, even for small lot orders. We also have many skilled craftsmen, all trained in-house, with more than fifteen years of experience in various fields.

Furthermore, we possess a precise modeling and painting technique using a brush that cannot be imitated by any other company. Our excellence in modeling and coloring, which requires a high level of realism and perfection, achieves the highest quality of product finish of its kind in the world.

For over twenty years, we have been the only company in Japan

that specializes in the high-quality, small-volume production

of polystone figures.

Material Used for Works of Art

We use Polystone (stone powder mixed with resin) as the main material for our products. Polystone is resistant to deterioration over time, is excellent for reproducing detailed modelling features, and has a stone-like texture and weight that is perfect for sculpting works of art.

Polystone is far superior to PVC and other plastic materials used by other companies in terms of fading and deformation over time. The stone-like finish and weight as a result of the stone powder in the material gives polystone figures a special sense of luxury.

Packaging

Complex and fragile final products are useless if they are damaged in transit. Polystone products have a high breakage rate so it is not uncommon for complex shaped items to have a breakage rate of over 20% when shipped overseas. We have developed packaging and shipping know-how over many years, conducted many drop tests under strict conditions, and used advanced technology to allow us to ship even complex items safely overseas. We are a specialist who fully understands the characteristics of a material that is fundamentally different from PVC products.

We provide the world’s highest level of packing and shipping service, especially regarding the prevention of damage to high-value products.

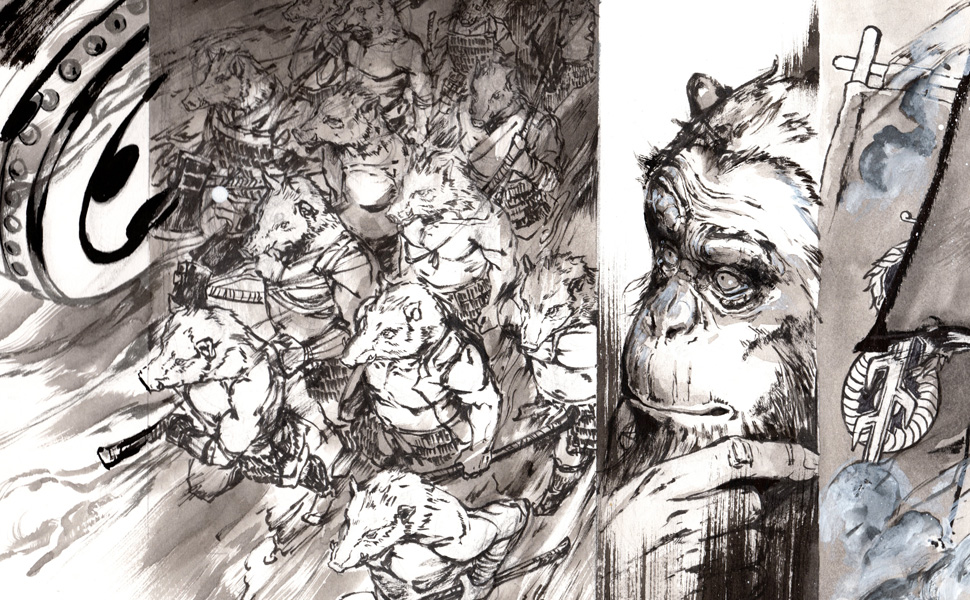

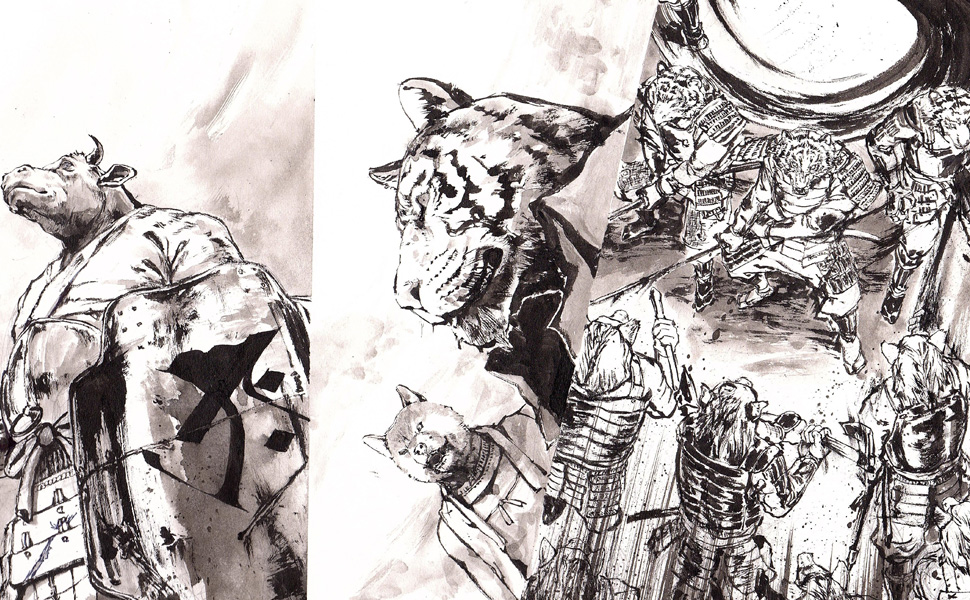

Product Development Samples

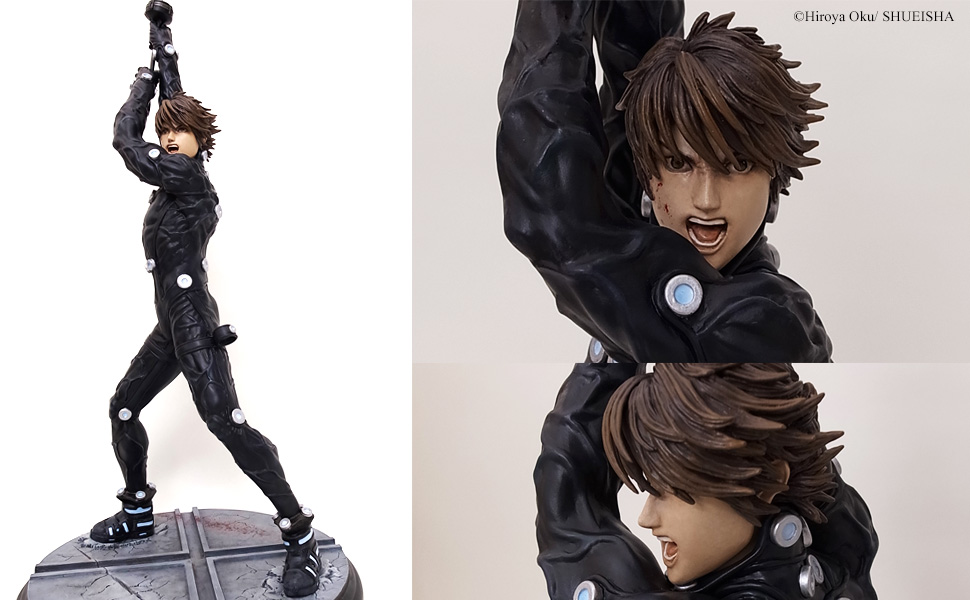

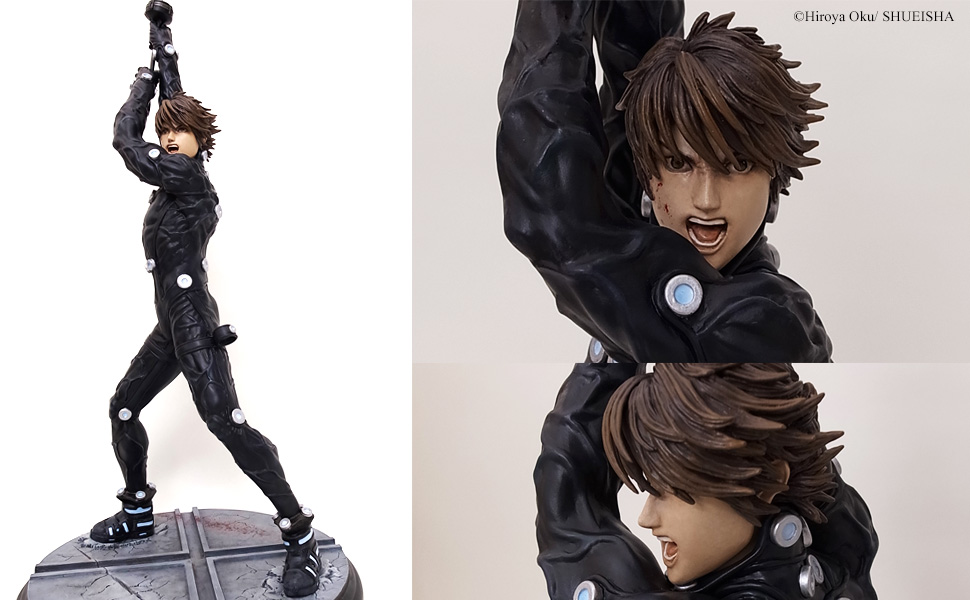

Kei Kurono

©Buronson・Haratetsuo/NSP,1983.

©Buronson・Haratetsuo/NSP,1983.

Kei Kurono

©Buronson・Haratetsuo/NSP,1983.

©Buronson・Haratetsuo/NSP,1983.

OEM Process

Please feel free to ask us anything about your first figure production.

Request an Estimate

Request an Estimate

Based on your requirements, we can prepare free cost quotations in about one week.

Colored Samples and Package Production

Colored Samples and Package Production

We will create a single-colored sample for approval and correction after finishing the mass production sample.

Product Shipping

Product Shipping

We will send the finished product to your designated warehouse.

The product will be shipped with packaging that has been thoroughly drop tested by us in advance. Please ask us any questions about shipping.

Production Details

Production Details

Upon agreement of the cost quotation, we will discuss the production details.

We will prepare a specification sheet

and make suggestions about the prototype and colored samples.

We can create prototypes or colored samples if you don’t provide one.

Commencement of Mass Production

Commencement of Mass Production

We will start mass production after your approval of the colored sample.

Production takes between sixty to ninety days depending on the number of products.

Any Questions?

Please enquire about cost-quotations.

You can also check the FAQs for answers to common questions.

Frequently Asked Questions

- Q. What is OEM?

- Q. What is Polystone?

- Q. What is the process from prototype to finished product?

- Q. Are the items machine produced?

- Q. Can we see samples?

- Q. How much budget should I prepare?

- Q. Do you accept product requests from private customers?

- Q. It is possible just to order a prototype?

Q. What is OEM?

A. OEM is short for Original Equipment Manufacturing, which means producing original products for other companies on consignment. We can handle OEM requests large or small, irrespective of whether it is a mass production or a hand-crafted small lot order created by our studio artisans. We can create a prototype or color sample if the customer is unable to provide one. Enquire for details.

Our experienced staff will supervise the production of prototypes and colorings to the customer’s satisfaction.

Q. What is Polystone?

A. Polystone, also known as artificial stone, is a material composed of stone powder in a high proportion to resin, often used for works of art and three-dimensional statues in Europe and the United States. The hardened weight and texture of polystone is very similar to natural stone and is durable. Polystone is strong but it is also fragile, especially if dropped, so care needs to be taken in the handling the material.

Please read the following notes about polystone and its features.

Since Art of War products are precision molded items, we conduct thorough drop tests in-house to ensure that they can withstand the shock of transportation and are delivered to our customers safely.

① Weight

Compared to soft vinyl and PVC figures, polystone is heavier and has a more luxurious feel, just like a stone statue.

Photos of items made of polystone

② Detailed Modeling

Polystone is often used for high-grade arts and crafts sculpturing and is excellent for detailed modeling.

③ Resistant to Deterioration

PVC products deteriorate greatly over time, and there is a tendency for the colors to fade and the shape to distort after purchase. On the other hand, polystone is resistant to heat deformation and fading, so it can keep its beauty for a long time. Polystone is an excellent material for long-term preservation and shape maintenance.

④ Highly Accurate Reproduction

Polystone is shaped in a silicone mold which is soft, flexible and easy to remove, even for complicated shapes. It even allows detailed features to be replicated. Since PVC figures are formed in a metal mold, it is difficult to remove the formed shape as it gets stuck in the hard mold. So, it is not possible to reproduce the detailed modeling features. For this reason, there is a big difference in the final look between PVC and polystone figures.

⑤ More Expensive

Polystone is made with silicone molds, which allows for the reproduction of complex and detailed shapes. However, we can make no more than ten units of a product with a single silicon mold because it is soft and the silicon can easily break.

This is a major difference with durable metal molds.

Therefore, we need to create new silicon molds each time, which results in higher production costs and more expensive polystone figures, especially when compared to toughter metal molds used for much larger quantities of cheaper PVC products.

A metal mold is different from silicone it is difficult to remove the shape of the shape that meshes with the hard mold, so it is not possible to reproduce the detailed modeling. For this reason, there is a big difference in the expression.

Q. What is the process from prototype to finished product?

A. We will create the basic shape in prototype form after deciding with the customer the type of figure and size to make.

We will create a mass production mold based on the prototype. Our molds are made of silicon which allow for easy die-cutting and reproducing complex shapes and details.

There are other types of molds such as metal, but silicon molds are less susceptible to manufacturing restrictions.

Liquid polystone is poured into the mold and once hardened, it has become an unpainted sample. We paint the sample, get the customer to check it, and do modifications if required. There are a choice of working materials but we use polystone. Visit our FAQ section on polystone for more details.

We will start the mass production after the customer approves the coloring. We follow the same procedure as the sample production, so after molding, the hardened polystone pieces are assembled and painted. We execute our procedures entirely by hand and directly supervise the manufacturing. This lets us achieve the highest level of quality control unattainable by other companies.

Finally, we package and ship the finished products to the customer’s choice of location.

Q. Are the items machine produced?

A. No. We do everything manually in our studio – from mold creation to painting, assembly, and packaging. Machine mass production is possible, however it becomes difficult to maintain the product quality for a high-standard figure. Our quality control is extensive. We work by hand to maintain high quality figures and lessen product deterioration.

Q. Can we see samples?

A. Customers are welcome to visit our showroom and view our samples. While our entire product range is not on display, you can view our works of art and crafts as examples of the high level of quality that we maintain in production. Photography is permitted in the showroom. Please click here for details for details on how to visit our showroom.

Q. How much budget should I prepare?

A. We will prepare a cost estimate for a customer’s consideration. The budget needed will vary greatly depending on factors including the production quantity, product size and image of the finished item. We can manufacture figures from miniature ones to large sizes. We are happy to answer any basic questions you may have. Please enquire for details.

Q. Do you accept product requests from private customers?

A. Yes, we do. We are experienced with OEM requests from individuals. Please contact us for details.

Q. It is possible just to order a prototype?

A. Yes. Please contact us.

Company Profile

| Name of Company | KENSIN CO., LTD |

| Trade Mark | ART OF WAR® |

| Date of Foundation | February 18th, 1997 |

| Address | B1/F, Nihonbashi Yuwa Bldg., 3-3-8, Nihonbashihongoku-cho, Chuo-ku, Tokyo 103-0021, Japan |

| Telephone Number | 03 (5299) 5617 |

| Fax number | 03 (5299) 5618 |

| President | Sakakibara Yutaro |

| Capitalization | JP¥10,000,000 |

| Business Outline | Original character licensing business, Consulting, OEM Manufacturing, Development and sales of in-house and licensed character toys and art crafts. |

| Trading Territories | Japan, North America, East Asia, Europe, Middle East, etc. |

| Major Clients | UBISOF EMEA, Hakusensha Inc., Shueisha Inc., North Stars Pictures Inc., De Agostini Japan KK., Nippon Television Music Corporation, Maruzen Co., Ltd, Mitsukoshi Ltd., NHK Promotions Inc., Shogakukan Inc., Togyoku Doll Co., Ltd., Yoshitoku Co., Ltd., Media Factory Inc., Capcom Co., Ltd., Business Association Amazon.com. Inc., eBay Inc., Warner Entertainment Japan Inc., Tsuburaya Productions Co., Ltd., Daiei Film Co., Ltd., Sammy Corporation, Konami Corporation, Yuke’s Co., Ltd., Cave Interactive Co., Ltd., Takeshobo Co., Ltd., ZenWorks Co., Ltd., Licensing International Japan, Tokyo Otaku Mode Inc. |

≪営業時間≫ 火曜日~土曜日(定休日:日、月、祝日) 10:00~18:00

Business Hours 10:00~18:00 (Tuesday- Saturday)

≪アクセス 最寄り駅≫ JR神田駅 南口より徒歩3分 / 地下鉄 銀座線 三越前駅(A8)より徒歩5分

Nearest Stations

-Kanda Station JR Yamanote Line (3 minute walk from South Exit)

-Mitsukoshimae Station Tokyo Metro Ginza Line (5 minute walk from A8 exit)

-Shin-Nihonbashi Station JR Sobu Line